![]()

Investigation Plan

To simulate industrial leaks, fluid escaping through an

orifice into ambient air is studied by measuring liquid drop sizes

and size distributions of aerosols forming at various distances

from the orifice. Measurements are made over ranges of temperature,

pressure, and orifice diameters. Measurements will be performed

for a variety of fluids that represent the range of fluids in industrial

use. Inhibition of aerosol formation also will be studied through

the addition of selected inhibitors.

Figures illustrate a physical procedure of spray break

up.

|

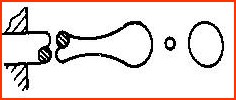

Rayleigh Regime: |

||

|

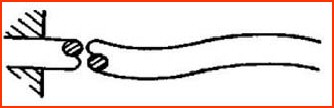

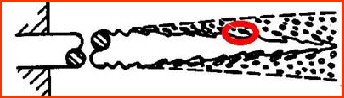

First Wind-Induced Regime : |

||

|

|

||

Twisted fluid

column oscillates with air friction |

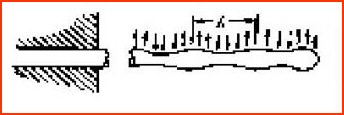

Wave-like

breakup caused by air friction |

||

|

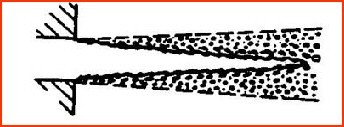

Second

Wind-Induced Regime : |

||

|

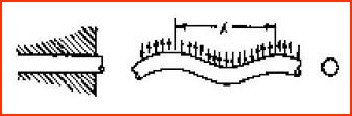

Atomization-Fully-Developed

Regime : |

||

|

|

|

|